Automation

Home » Technology » Automation

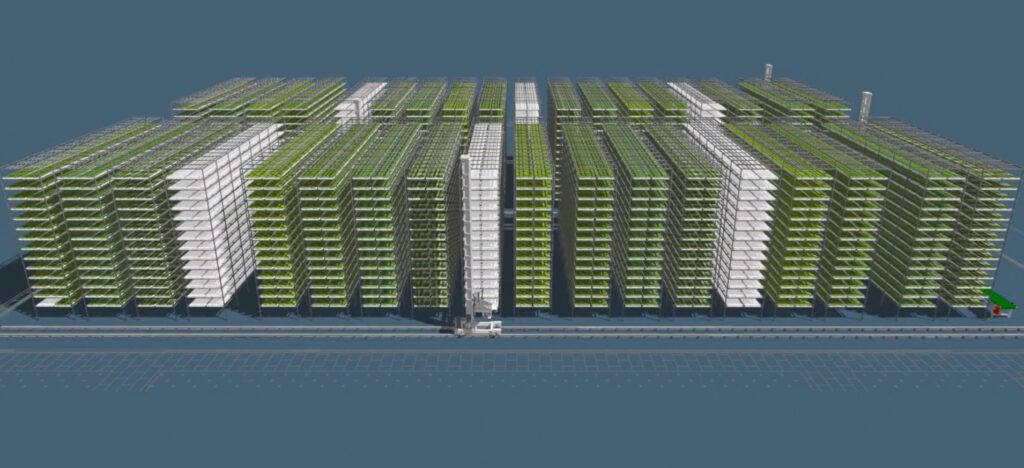

Nongshim Automated Vertical Farm System

“unmanned cultivation room + mass production + Minimize O&M”

MAXIMIZE

- 14 Tiers High Rack

- → Production Cpacity

SIMPLIFY

- Push-Pull Type Farm Stacker

- → Operation and Managemant

MINIMIZE

- Non-Driving Parts in Rack

- → Low Maintenance Cost

MAXIMIZE

- 14 Tiers High Rack

- → Production Cpacity

SIMPLIFY

- Push-Pull Type Farm Stacker

- → Operation and Managemant

MINIMIZE

- Non-Driving Parts in Rack

- → Low Maintenance Cost

Strong Effect of Vertical Farm Automation System

Comparison of Operational Efficiency with Existing Manual Models

- Factory with existing model 1,650 ㎡ size

- Automated factory 1,650 ㎡ size

Production capacity

Improved efficiency

30% increase

Improvements

- Spatial efficiency increased due to reduced gap between growing beds

- Reduced height limit of growing beds

Number of staff

Improved efficiency

30% reduction

Improvements

- Automation in growing room : Reduction in labor force

Efficient staff traffic

and safer work

Improved efficiency

Minimized work traffic No risk

Improvements

- Level height : more than 3m Unmanned work

Energy consumption

(per head)

Improved efficiency

20% reduction

Improvements

- Reduction in electricity consumption per plant by enhancing productivity per unit size

Energy consumption

(per head)

Improved efficiency

40% reduction

Improvements

- Improvements in bed cleaning work

- Auto-cleaner implemented

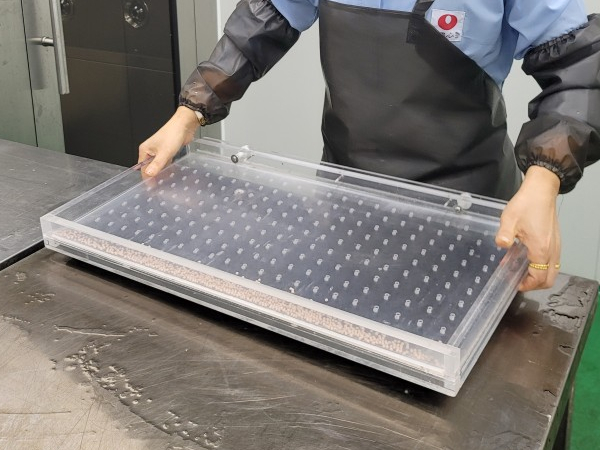

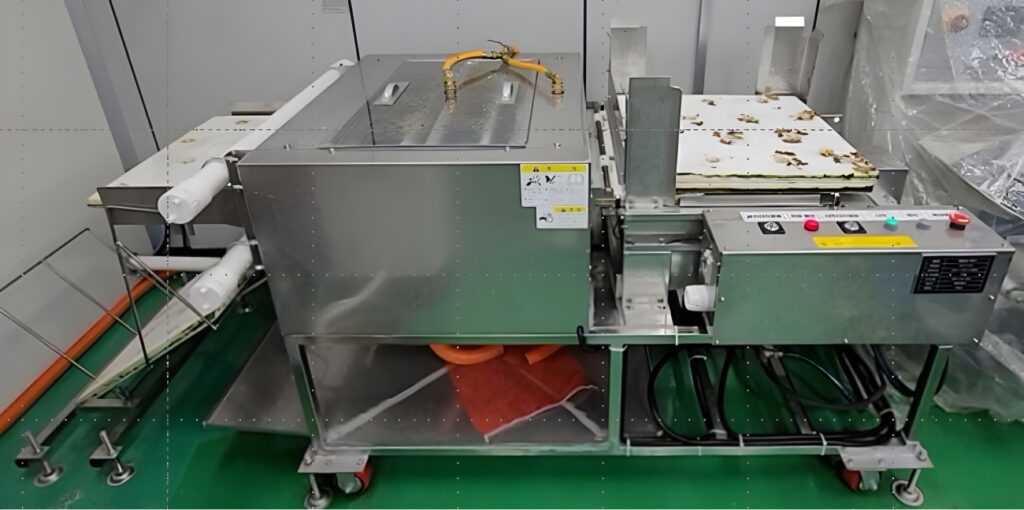

Development of Automatic cultivation tray washer

- Automatic cultivation tray washer (In-house development by Nongshim)

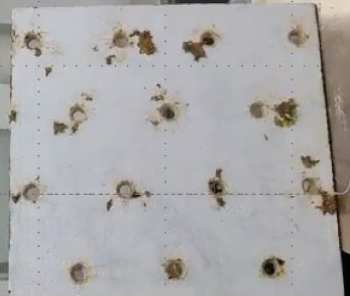

Cleaning test comparison

Portfolio

Nongshim Farm has expanded its business beyond Korea, providing innovative farming solutions in Qatar, Saudi Arabia, Oman, and other global regions.